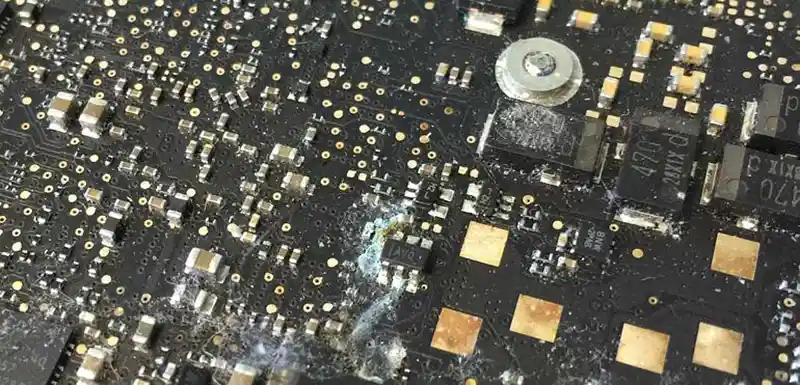

Despite being shielded by numerous essential components, a circuit board can still become vulnerable to ingress of water, dust, and dirt over time. Continuous exposure to these elements can lead to the corrosion of the circuit board, which may ultimately compromise the functionality of your device.

If you want to learn more about how to prevent and clean corroded circuit boards, please see and read the content below.

What Is Corrosion?

Oxidation transpires when oxygen interacts with a metal surface, leading to rust and the eventual flaking off of the metal surface. Given that PCB traces and pads are composed of metals like copper, they remain perpetually prone to corrosion.

Each metal exhibits a unique corrosion rate. Certain metals commence corrosion immediately upon exposure to oxygen, while some seem to remain impervious to corrosion entirely.

Causes of Corrosion on Circuit Boards

Rust on a board can lead to short circuits, and extensive corrosion can inflict irreversible damage to your device. Thus, before delving into methods for cleaning corrosion from motherboards or circuit boards, it’s crucial to comprehend the origins of such corrosion. This knowledge will empower you to adopt preventive strategies against the accumulation of corrosion.

Most circuit boards employ aluminum and copper as the principal metals for all conductive components. Regrettably, both metals are relatively reactive and can corrode upon exposure to atmospheric contaminants. Beyond airborne contaminants, liquids too can tarnish circuit boards. Both these hazards can be mitigated by maintaining your circuit board pristine and devoid of contaminants.

Types of PCB Corrosion

Corrosion can be categorized based on the underlying cause of metal degradation, as delineated below:

● Uniform Corrosion

● Galvanic Corrosion

● Localized Corrosion

● Intergranular Corrosion

● Electrolytic Dendritic Formation

● Fretting Corrosion

● Environmentally Induced Cracking

● Selective Leaching or Dealloying

● Erosion Corrosion

● High-Temperature Corrosion

Metals on PCBs predominantly encounter the initial five forms of deterioration listed above.

How To Clean a Circuit Board of Corrosion?

Over time, your PCB can amass more than mere corrosion. Particulates such as dirt, dust, and various contaminants can infiltrate your electronic devices. Regular cleaning can stave off corrosion. However, if corrosion has already manifested on your PCB, the subsequent methods can be employed to mitigate it and forestall additional deterioration.

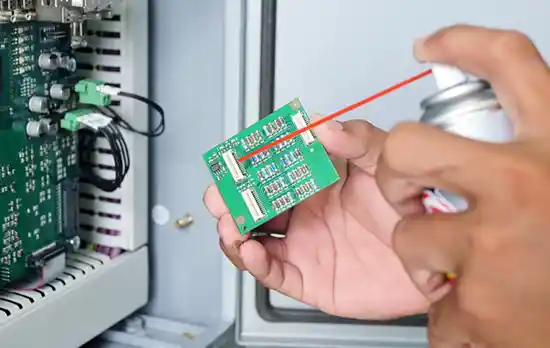

1. Compressed Air

Compressed air is a prevalent instrument for cleansing electronics. For straightforward maintenance tasks, it offers a non-invasive method to expel accumulated dust from electronic components or the interiors of devices. Administer the air into the ventilation ports in brief spurts. If remnants of dust persist, dismantle the device using a screwdriver and meticulously clear the circuitry with directed bursts of air.

2. Baking Soda

Baking soda serves as an effective agent for removing corrosion from PCBs. Comprising sodium bicarbonate, it acts on accumulated grime and dust on the PCB, disintegrating the debris into minute particles. The gentle abrasive nature of baking soda efficiently eliminates rust without introducing additional issues.

3. Deionized Water

When using water to clean a circuit board, ensure it is devoid of impurities. Ordinary water contains ions with conductive properties that can harm electronics. Conversely, deionized water is free from detrimental contaminants and ions.

4. Distilled Water

Distilled water is superior to other liquids for preparing cleaning solutions because it lacks ions that conduct electricity. This water undergoes a special purification process to eliminate harmful contaminants, ensuring the safety of the printed board.

However, it can easily become contaminated by airborne particles or residue from your hands. Therefore, always keep your distilled water supply sealed when not in use and refrain from handling it directly with bare hands.

5. Isopropyl Alcohol

Isopropyl alcohol, commonly referred to as rubbing alcohol, is adept at removing a variety of contaminants, including dirt, debris, flux, and rust from circuit boards. Its efficacy as a PCB cleaner is further enhanced by its cost-effectiveness and rapid evaporation rate. Additionally, compared to other similar cleaners, isopropyl alcohol has fewer chemicals. It’s imperative that the isopropyl alcohol used for cleaning your circuit board be at least 90% pure. High-concentration isopropyl alcohol can be harmful upon skin contact; therefore, when handling it, use precautions such as wearing latex gloves and protective goggles.

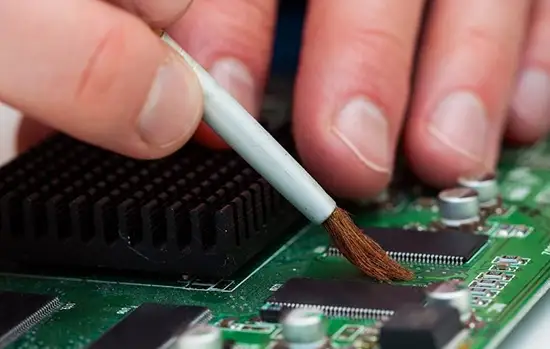

6. Thin, Soft-Bristle Brush

A brush is an indispensable tool for cleaning circuit boards, facilitating access between minute components. It is essential to choose a brush with soft bristles to avoid potential damage. The brush’s size is crucial to ensure that even the tiniest crevices are reachable.

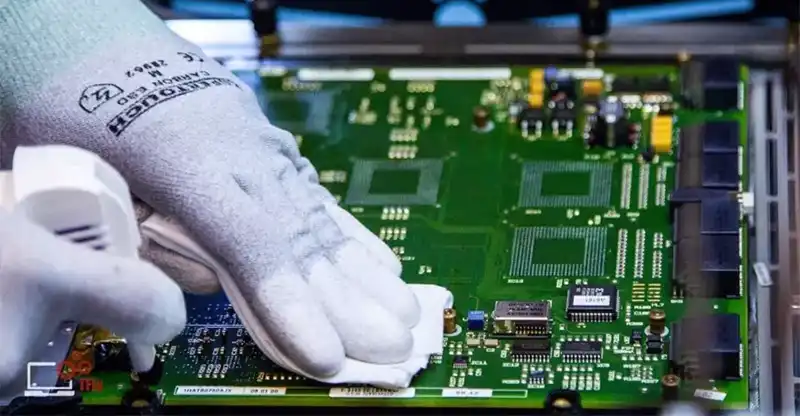

Many opt for commonplace tools like toothbrushes or paintbrushes, both for their durability and gentle bristles. Most households typically have one of these brushes on hand. Additionally, lint-free microfiber cloths are excellent for wiping and drying the circuit board post-cleaning.

7. A Blow Dryer or Hairdryer

Liquids may not always evaporate fully from a printed circuit board, necessitating additional drying. It is highly recommended to employ a heat source, such as a hairdryer or a blow dryer. As alternatives, a desk lamp or pre-warmed oven foil might also be effective.

How Do You Prevent Corrosion on a Circuit Board?

From the information provided, it’s evident that the primary culprits of corrosion on a PCB are moisture and electrolytic contaminants. PCBs are particularly vulnerable to various types of corrosion in challenging environments, especially those that are industrial or humid. To mitigate corrosion, one can:

● Ensure the PCB remains dry.

● Avoid allowing electrolytes to come into contact with the PCB.

● Use a conformal coating on the PCB.

● Diligently remove flux residues from the PCB.

Historically, if flux wasn’t removed post-soldering, it was infamous for producing chlorine or other detrimental halogens, leading to the pitting corrosion of copper traces. In contrast, modern fluxes employ organic acids, which are halogen-free and break down at elevated temperatures, such as during reflow soldering. Nevertheless, boards that undergo wave soldering might not achieve these high temperatures, making it imperative to meticulously clean any residual flux to stave off crevice corrosion.

Preventing moisture or other liquids from contacting the PCB is a crucial step in combating corrosion. Several strategies can achieve this, one of which includes housing the PCB within an IP-rated enclosure.

When enclosing the PCB isn’t viable, conformal coatings serve as an alternative. There are diverse types of these coatings, ranging from basic solder masks and aerosol spray coatings to epoxy coatings. All have proven effective in repelling corrosion. Nevertheless, when dealing with PCBs that have components generating heat, it’s imperative to apply these coatings judiciously to ensure they don’t disrupt heat dissipation.

How To Remove Solder Flux From PCB?

During the soldering process, two metals are bonded together using another metal with a lower melting point, which acts as an adhesive. Flux is essential in this process, as it safeguards the soldering joints from metal oxides that can hinder effective soldering. It achieves this by converting these metal oxides into salt and water, which are subsequently encapsulated by the solidifying flux.

Solder flux can leave a discolored yellow residue on chip pins where soldering took place. This issue often arises from improper handling of the circuit board, but it is straightforward to rectify. To address this, you’ll need:

● A soft-bristled brush

● A lint-free towel or microfiber cloth

● Anhydrous or rubbing alcohol with a concentration of 90% or higher

Dampen your brush with the rubbing alcohol and gently scrub the circuit board until the solder flux residue is eliminated. Once satisfied with the cleanliness of your board, pat it dry with the towel or microfiber cloth. While commercial cleaners or anhydrous alcohol can expedite the removal of flux and grease, using a high-concentration rubbing alcohol is a more cost-effective alternative.

How To Remove Corrosion From Electronics After Water Damage?

Addressing water-damaged electronics demands meticulous care. Inexpert attempts not only risk exacerbating the damage to the equipment but also pose potential personal injury hazards. It’s paramount to understand that electronic devices and liquids inherently conflict; hence, judiciousness must guide the application of cleaning solutions. For the general populace, it’s advised against undertaking repair efforts without professional guidance. An essential tenet to embrace is: When uncertain, always seek expert advice. With that understanding, consider the following insights when navigating the realm of water-damaged electronics:

● Before initiating the cleaning process on a water-exposed device, it’s imperative to disconnect any batteries, power cords, or external power sources. This safeguards against both personal harm and further device malfunction due to short-circuits. As a collateral benefit, you might uncover connectors that are already corroded. Exercise prudence during this step.

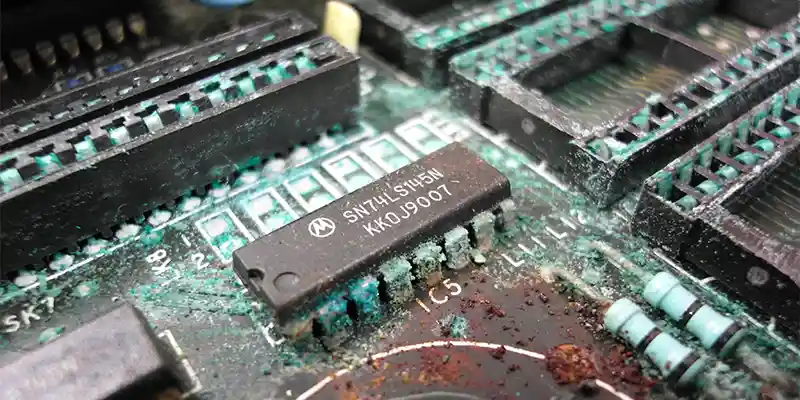

● Scrutinize the equipment for white or greenish residues, especially on battery terminals, charging ports, circuitry, logic boards, SIM card slots, and other significant metallic connectors.

● For cleaning, equip yourself with cotton swabs and choose a cleaning agent such as isopropyl alcohol, a blend of baking soda and water, or even vinegar. Delicately apply the chosen solution onto the corroded sections, gently wiping to and fro until the corrosion dissipates. If the corrosion persists, dampen the affected region with the solution and subsequently clear it off.

● To dry the electronic item, employ a soft cloth or utilize a hairdryer on its coldest setting. Refrain from using any form of heat. Before reinstating the battery or powering the device, ascertain that it is wholly dry, as lingering moisture could trigger further damage.

Conclusion

Corrosion has the potential to render a circuit board entirely nonfunctional, emphasizing the vital importance of apt cleaning measures. In this guide, we have not only discussed all of the important information about circuit board corrosion, but we have also provided a thorough guide on how to prevent and clean corroded circuit boards. Notably, forecasting corrosion in PCBs demands a seasoned eye, and oftentimes, pinpointing potential corrosion sites remains elusive until the onset of degradation. However, there’s a silver lining: corrosion-induced failure typically isn’t instantaneous, usually granting sufficient leeway to intervene effectively.